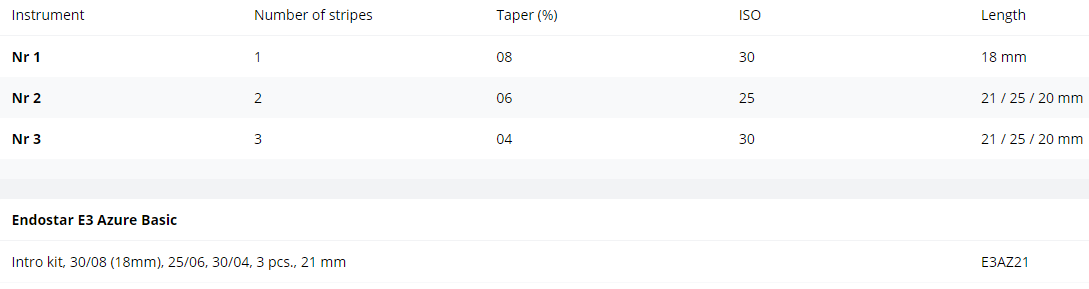

Description

Endostar E3 Azure is an innovative system created with Azure HT Technology which is our specially designed heat-treatment manufacturing process. The goal of Azure HT Technology was to create files that are extremely flexible and resistant to breaking even in the most complicated clinical cases.

- Safe - increased breaking resistance

- Extremely flexible - follows even the most curved canal path

- Effective and easy to use

- The thermal treatment of Azure HT Technology, which was applied to the nickel-titanium files, changed the crystalline structure of the nickel-titanium alloy. As a result, the transition temperature of the martensite phase to the austenite phase was reprogrammed around the body temperature. This process changed the properties of the files. You can bend them before inserting them into the channel. The files easily conform to the shape of even very curved canals, minimizing the risk of perforation, step formation or via falsa.

Endostar E3 Azure instruments can be repeatedly sterilized and used, provided that the visual inspection performed by the dentist prior to use shows that the instrument remains undamaged, is not bent, deformed, does not show signs of blade wear and can be securely attached to the handpiece. Particular attention should be paid to the winding (or excessive twisting) of the windings of the file.

The instrument windings should be regularly spread over the entire length of the blade, if in one point of the blade the windings are too close or too far apart (there is no regularity in the windings growth of the unused instrument), this is a sign that the instrument could break in the canal.

Permanent deformations of the instrument, especially bends, which do not have the form of an arc and have a visible break point should be always controlled before re-use. The heat-treated NiTi alloy allows these instruments to bend in the form of an arc.

In case of doubt, the file can be placed in any environment (fluid, air) at a temperature slightly above 40⁰C for a few seconds, then the blade should be straightened or curved on a very smooth arc. If the file is still deformed, it means it is permanently deformed and could not be use again. After each use, check that the blade is securely placed in the file grip. If the file has been subjected to high torsion force, especially in highly curved canals the instrument should be used only once.

Dispose of file which appears to be defective.

Files in the package may vary slightly in color, and the blades may be slightly arched. These differences do not affect the quality of the product. They are result from the applied heat treatment.

Files should be used with motor speed at 300 rpm.

The torque settings indicated in the table above table are for example only and may vary according to each user preferences and motor capabilities. Do not exceed the upper torque limit which is different for each instrument. If precise torque settings cannot be set, and only manufacturer-specific torque levels are available, be sure to select one that does not exceed the recommended limit.

-thumb_270.jpg)

-thumb_270.jpg)

-thumb_270.jpg)

-thumb_270.jpg)

0 Review for “Endostar E3 Azure Basic | Rotary Files”

5 Stars

0%

4 Stars

0%

3 Stars

0%

2 Stars

0%

1 Stars

0%